Spiral Jet Mill

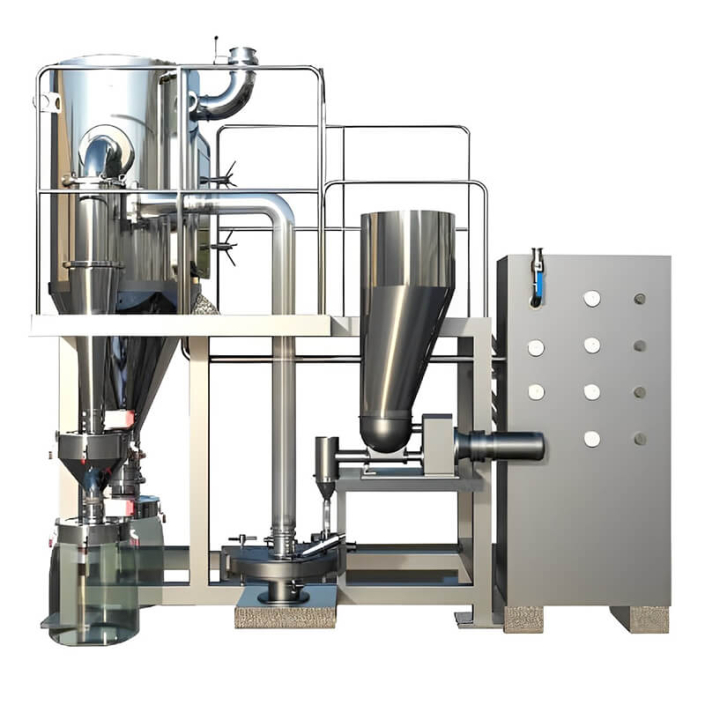

A Spiral Jet Mill is also called a pancake jet mill. The spiral jet mill is suitable for the fine and ultrafine size reduction of materials up to a Mohs hardness of 9 that display brittle crystalline grinding characteristics. They are typically used in applications where a high ultrafine portion is required.

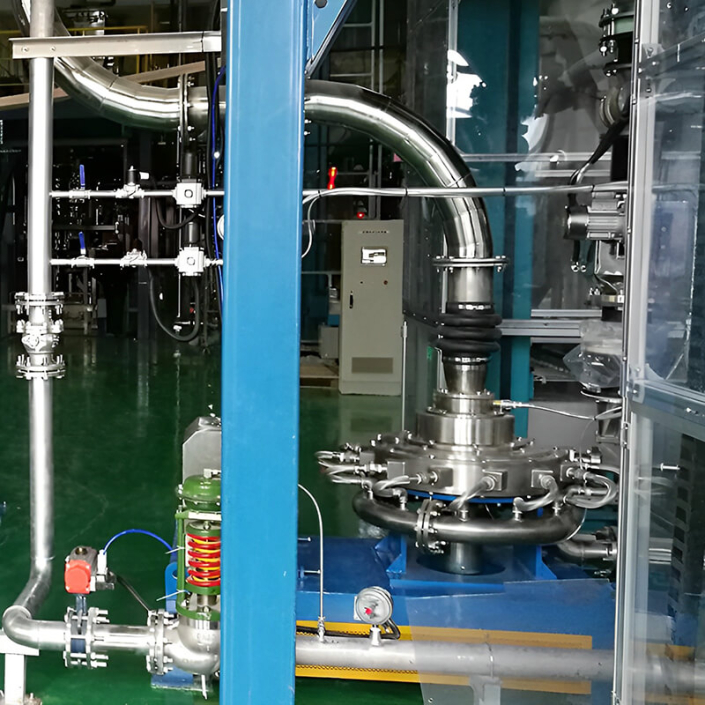

The spiral jet mill is simple in design, consisting of a flat cylindrical grinding chamber with several nozzles arranged tangentially in the peripheral wall, a pneumatic feed injector and a feed funnel. The spiral jet mill primarily uses impact grinding, while also performing attrition and cutting, with an automatic classification function.

How it Works

The feed is accelerated into the grinding chamber through the feed injector. The material inside the grinding chamber is subjected to two opposing forces: the free vortex created by centrifugal force (mass force) imparted on the particles by the nozzles, and the drag force created by the airflow as It spirals toward the center of the mill.

The larger particles are affected to a greater degree by the mass force, circulating around the periphery of the mill and colliding with other particles. As the particles become finer, the drag force exerts a greater effect, drawing the particles with the airstream to the central outlet of the mill.

Features

- Narrow particle size distribution improves bioavailability, reactivity and dissolution

- Spherical uniform particle shape increases pack density

- No heat created during milling protecting heat sensitive products

- Variety of interchangeable liners for maximum product purity

- Easy disassembly of mill parts for cleaning and inspection

- Engineered for simple clean up and product change over